It has been a while (to say the least) since I have written a blog post here and this is my attempt at starting again. I plan to do more restoration videos and have a few in the queue but first I wanted to write a brief post about my recent experience at the 2023 PMA Craft show. This show has always been a goal of mine, I have admired it and the craftspeople who show their wonderful work here every year. This year I finally gained enough confidence to apply and was pleasantly surprised when I was accepted in the emerging artists category. It was very exciting to get the news then at the same time, nerve wracking because now I had to build a booth and find time to build some new work.

I decided I had to build a booth with hard walls rather than the traditional pipe and drape booth that a lot of artists use. I made this decision so that I can showcase a few items that hang on the wall. The first was the walnut and cane hanging shoe cabinet that uses a French cleat to hang on the wall. Once I decided I’d have hard walls, I though it would be best to create a vignette that felt like a room. So I had a couple pieces that were my take on the traditional shaker rail using different woods like walnut and Sapele and giving them a pop of color with painted pegs. I’m really pleased how the booth looked. A few other pieces I had already completed included a Danish cord and walnut entry way bench, a cherry step stool, a walnut and cherry coat rack with a shelf and a wall sconce I had done last year (2022). With these pieced in mind I also wanted to do a credenza and a chair, and if I had time, a floor lamp to round out the room vibe vignette.

The first new piece I did was a simple three legged stool to get the creative jucies flowing. I have made this stool several times before in different wood types and choose cherry for this iteration. I really love how cherry darkens over time and this simple stool is very versatile. it can be a stool, side table or even a plant stand.

While I was doing the stool, in between glue drying and finish coats, I was planning a chair. I designed a simple lounge chair, or slipper chair as I like to call this one. Its a low lounge chair made from Sapele and features a cane back and an upholstered seat cushion. I then decided to add a low lumbar cushion to the back rest to provide additional comfort while not hiding the cane work that I really like. If you look closely at the chair there are a few design details that I am really happy with. I really like the lines and the seat angle. The joinery is all wedged tenons and the cane really makes the chair stand out.

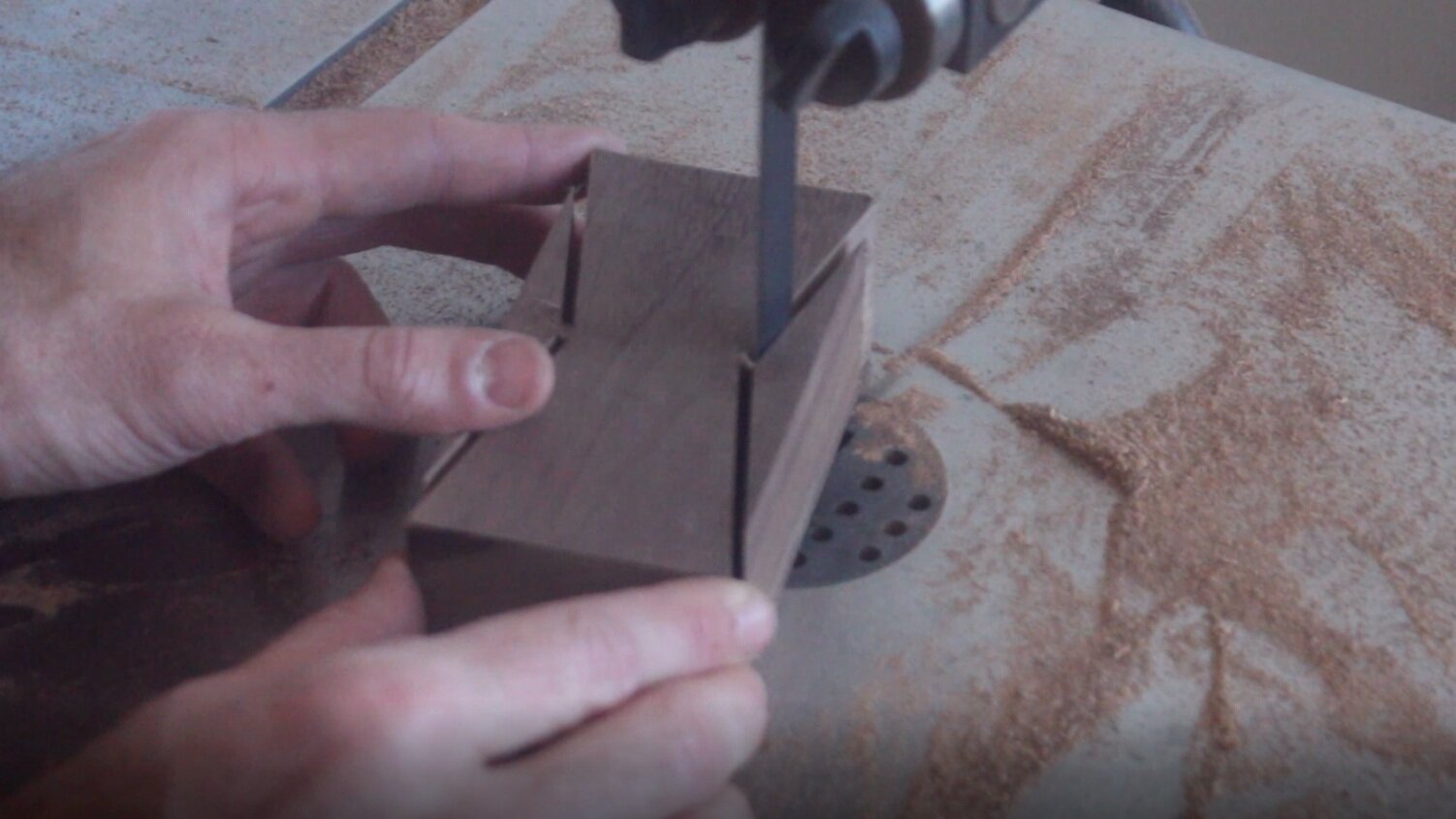

I knew I wanted to make a case piece and I wanted to do dovetails. Other than that I didn’t really have a design in mind. I ended up doing solid Walnut. the Top and sides of this piece were all one single board. I sourced it from Hearne Hardwoods in Oxford, PA. It took me a few practice tries on the dovetails to get them dialed in and then I committed and did them on the walnut. Once I had the case assembled I was deciding how to do the doors, I thought about a tambour door but ended up going with leather front sliding doors. I haven’t worked with leather in this way before but have been thinking about integrating in for a while. I had this amazing green leather hide for a few years and decided it would look great with the walnut. I think the leather is going to patina amazingly with lots of use. after doing the doors, next were the legs and pulls. I headed to the lathe and payed with a few profiles and ended up with what you see in the photos

Once I finished the credenza, just in time, I had about a day left to recover and decided that I had enough time to make a lamp. I had some Ash Lumber and with the help of my buddy Ben at Ovuud, an expert at lighting design and building. He helped me with some spare parts he and and some extra ash lumber. the lamps construction was pretty straightforward, I had thought bout the build process overnight and hit the ground running when I got to the studio on Monday morning before the show. I was able to do everything in a day(long day) I’m super happy how this reading lamp turned out and I think it was the icing on the cake for my booth.

Now that I had all my pieces done all that was left was packing the van and the booth set up. It took me about half the day on the Tuesday before the show to pack the van. Wednesday morning I had a 930 entry time and was there right on time. I was able to drive the van onto the show floor and get set up. It took me about until 2 or 3 to get all set up. I met quite a few other vendors and everyone was really nice and helpful..

Thursday afternoon / night was the judging for the prizes and then the preview party. This was a great experience, although I didn’t get a chance to see the judges or talk to them but knew that they had a chance to take a look at all the artists. Al the winners were announced at the start of the preview party and then everyone in attendance got a first look at all the wonderful art. I had a chance to meet a few people I knew and some previous clients which was an unexpected surprise. The next 3 days was the actual show that was open to the public. I had a great time talking to all the people that showed up and was able to network with a lot of potential clients and I also had a chance to talk with a bunch of the great artists. The Women’s Committee of the Philadelphia Museum of Art did a great job with the show, from the very start with communication and all the Q&As to the set up and tear down. I had a wonderful experience and I hope over the next few months I will start to see a few commissions from the show. I do plan to apply for the 2024 show as well and you will have to stay tuned over the next year to see any new work I design and make, maybe you will get a chance to see them at the show next year.